At the bottom of the page is complete list of all our detail part pages

Mining

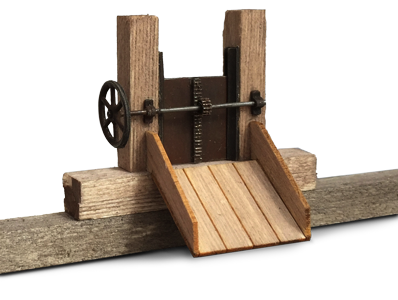

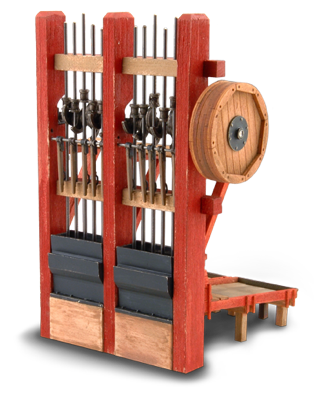

Grizzly

Now available in these scales:

HO scale–$12.99 | S scale–$14.99 | O scale–$17.99 | 1:20.3–$26.99

As our Detail Parts page grows, please be sure to scroll all the way down.

Click on the part numbers below to jump to a particular item or scroll through all of our details on this page!

Now available in these scales: (2 per package)

HO scale – $12.99 | S scale – $14.99 | O scale - $16.99

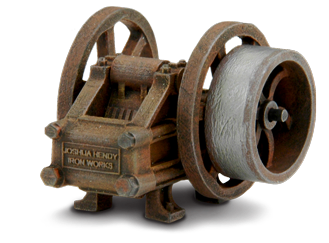

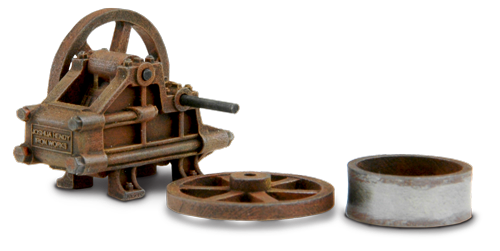

Joshua Hendy

Rock Crusher

Mining

Ore Bin Gates

NEW mining kits are now available!

Now available in these scales:

HO scale–$49.99 | S scale | O scale–$59.99

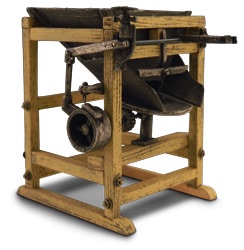

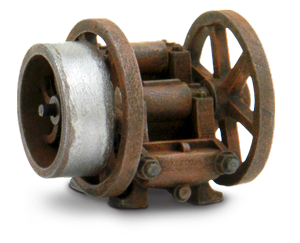

Challenge

Ore Feeder

These are rack and pinion style ore bin gates. Two are included in a package. In a mill, one gate would feed one ore feeder. These kits now include the laser cut chute shown above.

Now available in these scales:

HO scale | O scale–$59.99

3 Stamps

Even though this portable 3-stamp battery is much smaller than the large permanent batteries (shown below), it works in exactly the same way. The 3-stamp prospecting battery was made by Fulton Engineering and Shipbuilding Works of San Francisco, California. Small stamp batteries like this one, were deigned so that they could be easily taken apart for transportation and re-erected without cutting or fitting. There are no mortar blocks or foundation required, as the mortar rests on cross sills held to the main frame by heavy bolts. The stamps each weigh 250 pounds. They make 90 drops per minute and can crush from 3 to 4 tons of rock per day. The total weight of the 3-stamp mill including the wood frame would be around 4500 pounds.

Now available in these scales:

HO scale–$89.99 | S scale–$99.99 | O scale–$119.99 |

Gold Mill Stamp battery

10 Stamps

M2 – Rock Crusher

M3 – Ore Bin Gates – Two (2) ore bin gates/package

M4 – Challenge Ore Feeder –

M5 – Portable 3 stamp battery –

M1 – Grizzly

10 stamp battery #M6 –

Detail Parts - Mining

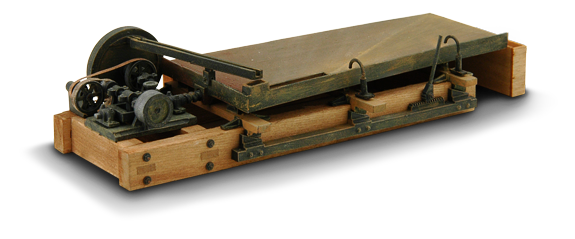

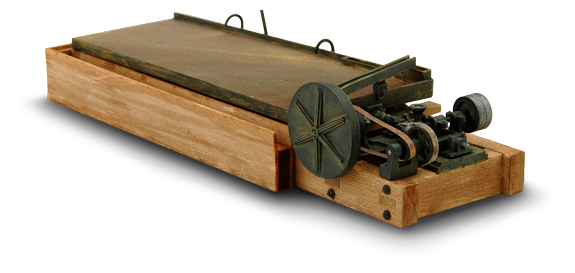

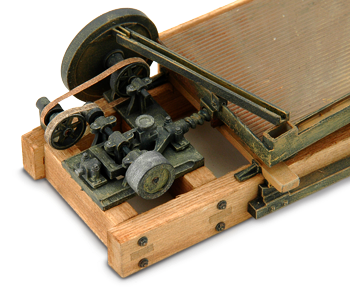

Wilfley Table

Wilfley Table #M7 –

Now available in these scales:

HO scale–$24.99 | S scale–$26.99 | O scale–$29.99 |

Clean-up Barrel

Clean-up Barrel #M8 –

Part # M1:

Part # M4:

Part # M3:

Part # M5: $59.99

Part # M7:

Part # M8:

Automatic ore feeders are used to eliminate hand feeding of material into the stamp battery. The Challenge ore feeder has an iron hopper that collects ore from the ore bin. Under the hopper is a circular table inclined toward the stamp battery mortar which slowly revolves.

The fixed scrapers directs ore into the back of the stamp mortar as the table rotates.

The stamp battery regulates the flow of ore into the stamp mortar by controlling the rocker arm connected to the ore feeder. When the stamp mortar is full, a tappet on the stamp stem is too high to strike the rocker arm. When material is crushed and removed from the mortar, the stamps are able to fall lower in the mortar and the rocker arm will again be stuck by the tappet causing the table to rotate and feed more ore into the mortar. The amount of each movement can be also be controlled by the ore feeder.

Further operational details are included in the kit!

Includes (2) two ore feeders

A gold mill houses the equipment necessary to remove gold from the surrounding waste rock, either by concentrating it or by mechanically separating it.

The stamp battery is the heart of a stamp mill and the mechanical separation process to break the various components of the ore apart, freeing the gold from its enclosing material.

To start, the mined rock enters the mill and passes over a grizzly (like a grate-kit# M1) that has bars spaced to allow rocks that the stamp battery can handle to drop through. If the rocks do not drop, they are sorted and crushed with a rock crusher (kit#M2). The rock is then dumped into an ore bin until being fed through ore bin gates (kit# M3) into an ore feeder (kit# M4), then into the stamp mortar. When the rock runs through the stamp battery, the finely crushed mixture is washed over a series of copper plates coated with mercury (amalgamation tables) where the freed gold combines with the mercury to form what is called amalgam (the process of amalgamation). The amalgam is scraped off the plates and put into a retort where the mercury is driven off, leaving the gold behind.

In many mining districts, gold was found in close association with compounds of other metals such as iron, copper, lead, or zinc, preventing the gold from coming into contact and amalgamating with mercury. This type of gold ore is known as refractory gold and requires additional concentrating machines, such as Frue vanners or Wilfley tables (kit# M7) to complete the extraction process. The concentrate from these machines could be treated by a cyanide process or sent to a smelter to free the gold.

"Historically, ninety percent of the quartz crushed in California and most of the western United States was pulverized by stamps."

History:

Two (2) laser-cut amalgamation tables with amalgam collectors are included. Details also include the cleaning platform and "metal" plates.

Our stamp battery now includes, along with the original WSM castings, a realistic wooden cam pulley, maintenance platform with bracing, two laser-cut amalgamation tables, pre-cut heavy wire for accurate stamp rods, new cam design, nut/bolt/washer castings, and laser cut wood posts and beams for a perfect, precision museum quality assembly. We have updated the original Western Scale Models assembly instructions to resemble our trademark step-by-step fully illustrated instructions.

Everyone from beginners to experts can enjoy building this detailed stamp battery that will certainly be a conversation centerpiece of any mining layout and collection.

The back view shows the latch fingers that are used to disabled the stamps for cleaning. The rear of the mortar box where the ore feeders dump the rock from the ore bins, is also shown.

How it works:

The Design

Rock crushers are reciprocating- pressure breakers. They consist essentially of two crushing surfaces set at a small angle convergent downward, one fixed, the other movable, which approaches and recedes alternately from the fixed crushing surface. This model is based on a Joshua Hendy style rock crusher.

The Wilfley table was made and patented in 1896, by Arthur R. Wilfley and first used in his mill at Kokomo, Colorado. The first table was sold in August, 1896, and by 1925, more than 22,000 Wilfley tables were in use. The table's great advantage was that it made a clear and distinct separation of various types of minerals based on their specific gravity. Many variations of the Wilfley table followed the initial design but they all worked on the same principle. The Wilfley table revolutionized ore dressing. Our model is designed after one of the early tables, so it can be used in any mill after the late 1890's.

Includes (1) one wilfley table

Part # M6:

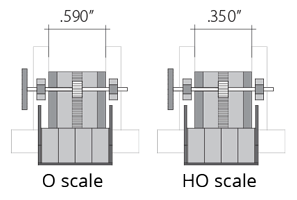

O scale

HO scale

Available in HO, S, O scales

Part # M2:

Click on the small arrows to the right of the product to see all of the scales available.

Available in HO, O scales

Click on the small arrows to the right of the product to see all of the scales available.

Available in O scale

Click on the small arrows to the right of the product to see all of the scales available.

.375"

Portable Stamp battery

Used in hard rock mining, we offer different types of hand pushed ore cars, as seen below. Each is unique to the different needs of the mine operation. These ore cars were pushed on 18" wide tracks.

Click on the image to go to our dedicated ore cars page.

DP3 - Scoop Dump ore car

DP1 - Rotary Dump ore car

DP2 - V-Dump ore car

DP5 - Outhouse ore car

Now available in these scales:

HO scale–$49.99 | S scale–$59.99 | O scale–$69.99 |

Now available in these scales:

HO scale–$19.99 | S scale–$21.99 | O scale–$24.99 |