At the bottom of the page is complete list of all our detail part pages

Detail Parts - Logging

Now available in these scales:

O scale - coming

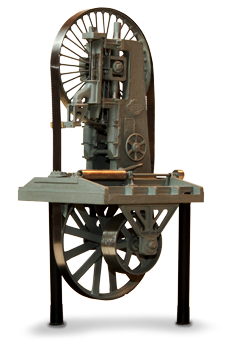

L1 – Band Saw 10'- Sumner Iron Works

Now available in these scales:

1:20.3 scale | HO, S, & O scale in development

Double

Circular Saw

L3 – Double Circular Saw

Now available in these scales:

1:20.3 scale

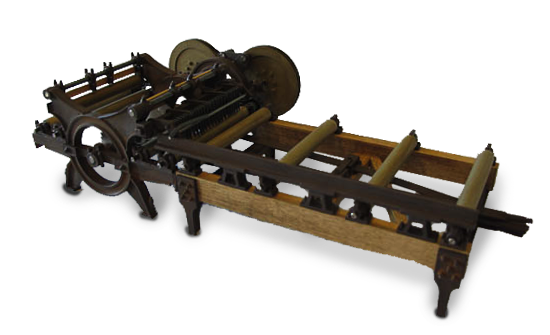

L4 – 4 Block Log carriage

Now available in these scales:

1:20.3 scale

Cut-off Saw

L5 – Cut-Off Saw

Below are detail parts and kits that relate to the Logging Industry.

Click on the part numbers below to jump to a particular item

or scroll through all of our details on this page!

We will list, under the "sticky notes", the kit scales that are currently available. Some of these kits were only designed and available for 1:20.3 scale.

It is our goal to make all of these available in HO, S, and O scale in the future!

L12 - Transfer Rolls (dead & live)

L13 - Log Carriage Steam Engine

L15 - Pulleys/Bearings (saw mill)

DP21 - Single Cylinder Steam Engine

DP23 - Horizontal Brick Boiler

Now available in these scales:

1:20.3 scale

L7 – Edger

Now available in these scales:

1:20.3 scale

L8 – Log Deck Turner

Now available in these scales:

1:20.3 scale

Overhead Log Turner

L9 – Overhead Log Turner

Now available in these scales:

1:20.3 scale

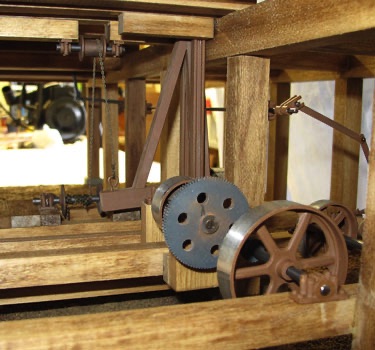

Log Haul Winch

L11 – Log Haul Winch

Now available in these scales:

1:20.3 scale

Transfer

Rolls

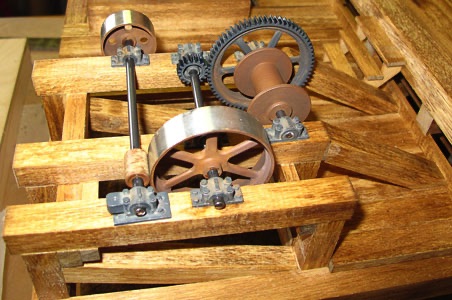

L12 – Transfer Rolls

The cut-off saw kit consists of a 24" dia. saw blade on a swinging frame. It would be used in a small sawmill to trim the ends of the cut lumber to make it square and of a standard length. Boards can also be cut into shorter lengths to eliminate defects and raise its grade.

Our double circular saw is modeled after an Allis Chalmers design. It includes a 60" dia. lower saw with drive pulleys, saw guide and log spreader. The upper saw is a 36" dia. saw with drive pulley, belt reversing pulleys and control arm, and a mechanism to raise and lower the upper saw for alignment.

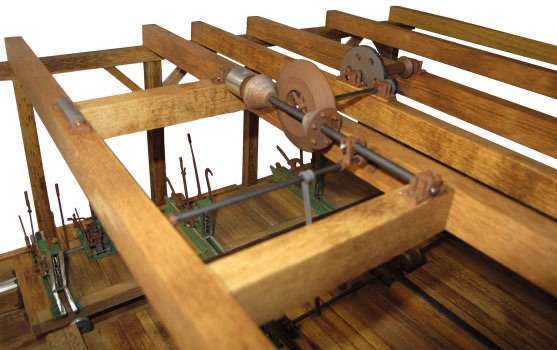

Our 4 block log carriage is modeled after the log carriage at the McLean Sawmill, Port Alberni, Canada. It was originally assembled in 1926 and rebuilt in the 1990's to match the original design as close as possible. We have made the model carriage 28' long, but it can be made smaller to adjust to your needs. The kit includes over 150 white metal castings with four blocks, setworks and setworks drive, wood frame and cable drive. The carriage is a perfect match for our double circular saw above (L3).

4 Block

Log Carriage

Edger

Log

Deck Turner

Available in O scale only

Available in 1:20.3

Available in 1:20.3

Available in 1:20.3

Available in 1:20.3

Available in 1:20.3

Available in 1:20.3

Available in 1:20.3

Available in 1:20.3

The edger puts a square edge onto wood, and with the use of multiple blades, cuts the wood to the desired width. It consists of a front feed table with dead rollers, a central frame with saws, feed and press rolls, driving pulleys and saw shifting arms, and a rear table with live rollers to carry wood away. The edger has a total of 10 rolls, 4 on the feed table, 4 live rolls and 2 press rolls on the edger.

Our log deck log turner includes all of the pulleys, bearings, gears and controls that would be needed to install and operate it. The equipoment is modeled after that used in the McLean Sawmill located on Vancouver Island, British Columbia, Canada.

The overhead log turner at the McLean Sawmill is driven by a steel friction wheel and two cone shaped friction wheels which provide movement in both directions. One end of the chain is attached to the drum and the other end to a canting hook.

The Log Haul winch pulls logs from the log pond below up a ramp into the sawmill. It consists of a cable drum, small and large gears and small and large friction pulleys to reduce the speed of the cable. A reversing friction cone pulley arrangment is located in the basement to change the direction of motion on the cable.

Transfer rolls are used to move cut lumber through the mill from one station to another and eventually out of the mill onto the green chain. Rolls are either "dead" or "live". The dead rolls spin freely while the live rolls are driven to move lumber through the mill. Rollers are typically 8 to 12 inches in diameter and 30" wide mounted approximately 4 feet apart. They are supported by bearings on a wood framework, generally 30" above the floor. They are either driven by miter gears or by an endless chain. A reversible friction drive is used so that the rollers can be reversed if necessary.

Our kit consists of 1/2" by 1-5/8" aluminum rolls with bearings, wood and wire. The live rolls are driven by miter gears. The drive mechanism includes a friction cone pulley to reverse the direction of motion.

Part # L3: $ TBD

Part # L4: $ TBD

Part # L5: $ TBD

Part # L7:

Part # L8: $ TBD

Part # L9: $ TBD

Part # L11: $ TBD

Part # L12: $ TBD

10 foot

Band Saw

Part # L1: Sold out

Temporarily

Sold Out

Temporarily Out-of-Stock

Temporarily Out-of-Stock

Temporarily Out-of-Stock

Temporarily Out-of-Stock

Temporarily Out-of-Stock

Temporarily Out-of-Stock

Temporarily Out-of-Stock